nextgen™ – the ultimate benchmark

nextgen™ connectors define the technological boundaries for A/V connectors

Nowadays, what has always been the driving force behind WBT is common knowledge:

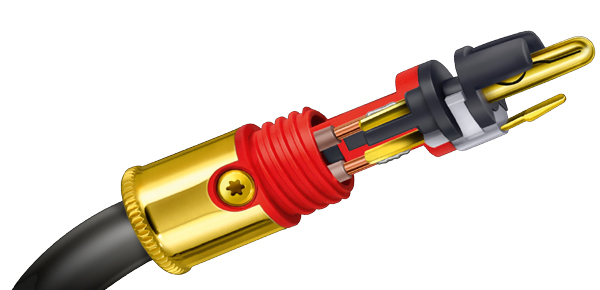

Connectors are far more than simply electrical contacts. We know about the importance of mass storage effects or the influence of materials used, and even the shape of these materials, on signal transfer. WBT has been carrying out fundamental research for over 20 years now and, with nextgen™, has conceived a product range that, and it is no exaggeration to say, defines what is currently possible in technological terms.

There are fundamental differences between connectors from the WBT nextgen™ series and conventional connectors; starting from the materials used and moving on to the manufacturing process.

Benefits of nextgen™ at a glance

Unhindered signal transfer through mass optimisation

- Around 90% reduction in metal mass, so no mass storage effects. This improves audio spatiality considerably.

Purer signal transfer

- Losses as a result of eddy currents are practically eliminated thanks to the

new geometry. So the signal is clearer, like it has been removed of any extra baggage.

Stronger foundations

- Through pure, soft copper (optionally also fine silver), the internal resistance of the contact materials is optimised significantly. The sound is given much more substance.

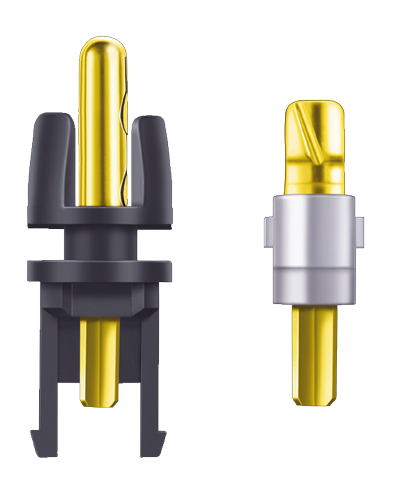

Real, standard-compliant RCA connectors with 75 ohms

- nextgen™ RCA connectors consist of connectors and sockets and are future-proof. Thanks to the 75-ohm line impedance, they are also finally able to carry digital signals with a bandwidth of up to 1GHz. Analogue signal transfer also benefits considerably from the enormous bandwidth.

Contemporary & green

- The modern, hybrid manufacturing process saves 90% of valuable non-ferrous metals (copper and brass) whilst increasing the technical and sound performances at the same time. This makes it unique.

The nextgen™ principle is the first technique which allows pure copper or fine silver to be used as signal conductors without compromising on robustness and the long-term behaviour of the connectors.

Conventional connectors are turned parts, meaning that copper is actually relatively unsuitable as a material as it is too soft. That is why stronger alloys are used in the manufacturing process. The electrical conductivity of these alloys is poorer than that of pure copper or fine silver. As the connectors are usually made solely from metal, there is also a danger that mass storage effects and eddy currents occur which affect the signal transfer and therefore represent a further reduction in quality.

WBT nextgen™ connectors do not have to deal with this problem. They are the only connectors which take the latest findings from the fields of electrical and mechanical engineering into consideration.

Losses resulting from eddy currents and the mass storage effect are eliminated by the reduction of metal and the use of modern materials. The actual signal conductor consists of pure copper or fine silver (no alloys!). Thanks to the nextgen™ composite technology, the mechanical robustness is in no way inferior to that of our globally-established classic series. nextgen™ provides audible and measurable quality and has exhausted the potential of what is technically possible.

Using nextgen™ connectors has clear advantages whatever the application. RCA connectors and sockets have a line impedance of 75 ohms in accordance with the latest standards – the perfect basis for perfect digital signal transfer. With a bandwidth of one gigahertz (conventional connector bandwidth is a mere fraction of this), the models are also state of the art when it comes to analogue signal transfer. Speaker connectors also benefit to a significant extent from the technological progression made possible by nextgen™ technology. In addition, our pole terminals have unique optimised conductor geometry which has been determined over the course of countless testing and measurement processes. For the first time, this allows the highest possible transfer safety in consideration of the disruptive influence of structure-borne sound. More information about this important subject is available on the following pages.

Alongside these invaluable advantages, nextgen™ also conserves important resources and are – just like all other WBT products – manufactured exclusively in Germany using modern and environmentally-friendly methods. nextgen™ connectors define the ultimate state of the art.

nextgen™ is a WBT development line and internationally patented. WBT ® and nextgen™are registered trademarks of WBT Germany.

WBT-signet™ is an internationally protected symbol of quality and originality. Forgery-proof!