Completely made in Germany!

Made in Germany – that‘s not simply some kind of empty promise for WBT, rather a mission statement that the company has lived for over 25 years and an asset that is worth protecting.

The reasons are simple. Right from the start with the introduction of the legendary WBT-0100 RCA connector in 1985, the goal was always oriented towards manufacturing technically-innovative but also simple and high-quality connectors. This requires an extraordinarily high level of series stability and processing quality.

We still believe the only way to guarantee this is with in-house WBT manufacturing.

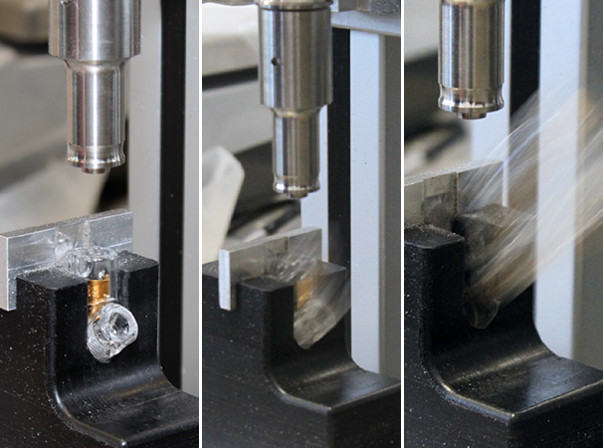

Even if high-quality classic connectors are able to be produced in low-wage countries nowadays – many of which are oriented towards WBT – production in Germany has always been a decisive factor for us. The standards are extremely high in terms of production and manufacture. Each of the tools essential for the production process is a masterpiece. They must work to an accuracy of 1/1000th of a millimetre, otherwise they simply aren‘t good enough for WBT. Dozens of tools are required to produce the range of WBT products and this alone explains why this expertise is unique.

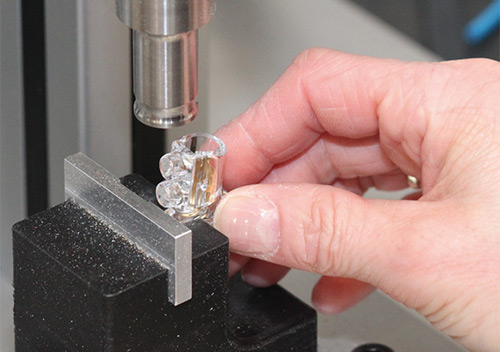

Modern connectors in the nextgen™ series consist of very different functional materials, which only complement each other perfectly when combined. This is where precise manufacture and the craftsmanship of our employees are a guarantee for constant, first-class quality.

Pure copper or fine silver is used as a signal conductor in nextgen™ connectors. The surrounding body consists of modern functional materials. Directly around the soldering joint, for example, the base body must cope with high temperatures and may not deform. Conventional PVC is unsuitable here. This also applies to production. After the signal conductors have been manufactured using the specialised tool, they are deburred, cleaned and then gold-plated (Cu parts) directly without any nickel (!) being used. Subsequently, the conductors are put through a complex coating process using a functional material. Only when the temperature and pressure conditions are in perfect harmony does the base part comply with the high standards we set of nextgen™ connectors. With nextgen™, what was previously a simple turned part has been transformed into a qualified interface.

The conventional plastic parts such as the clamping nut and the plastic ring are also manufactured by a high-precision extruder. This is no place for standard plastics, as they wouldn‘t be able to withstand the mechanical loads on parts such as the thread. The modern nextgen™ connectors are also superior to their metal-based contemporaries in terms of long-term robustness and contact safety. In this respect, it‘s just like the situation in the automotive sector – namely that modern, functional materials are replacing heavy metal components on an increasing basis, without having to compromise on safety or quality.

On the contrary:

nextgen™ connectors set technological standards in every respect and also preserve valuable resources of non- ferrous metals.

You see, decades of knowledge and experience are invested in WBT products. Such sophisticated products also attract the envy of others who want to save enormous development costs and plagiarise our models, albeit with negligible success. Products, which definitely do not meet WBT standards and are certainly not manufactured in an environmentally-friendly manner.

Today we define cutting-edge technology with nextgen™. We dedicate all our expertise to nextgen™. Which is one good reason to protect ourselves against counterfeit and imitation products. This is the only way to guarantee that our customers receive what they are entitled to, the best connectors in the world. Therefore look out for the WBT signet®. This small sticker, which is also made of several functional materials to secure against forgery, guarantees that you have a genuine „Made in Germany“ WBT original in front of you. Quality that you and your hi-fi components deserve.