HIGH END 2024

19.05.2022 - 22.05.2022

M,O,C, Munich

Lilienthalallee 40

80939 Munich

Germany

Atrium 4.1, E126

What´s new? A great deal. Sound improvement, security and innovation, and all this in the familiar WBT and nextgenTM quality.

Visit us on the next exhibition:

19.05.2022 - 22.05.2022

M,O,C, Munich

Lilienthalallee 40

80939 Munich

Germany

Atrium 4.1, E126

In the 2021 Germany-wide innovation competition, organised by WirtschaftsWoche*, EnBW and accenture under the auspices of the German Federal Ministry of Economic Affairs and Energy, WBT was chosen as the winner for its WBT-PlasmaProtect™ PVD process development.

The contact quality and long-term stability of audio connectors can be improved with this process:

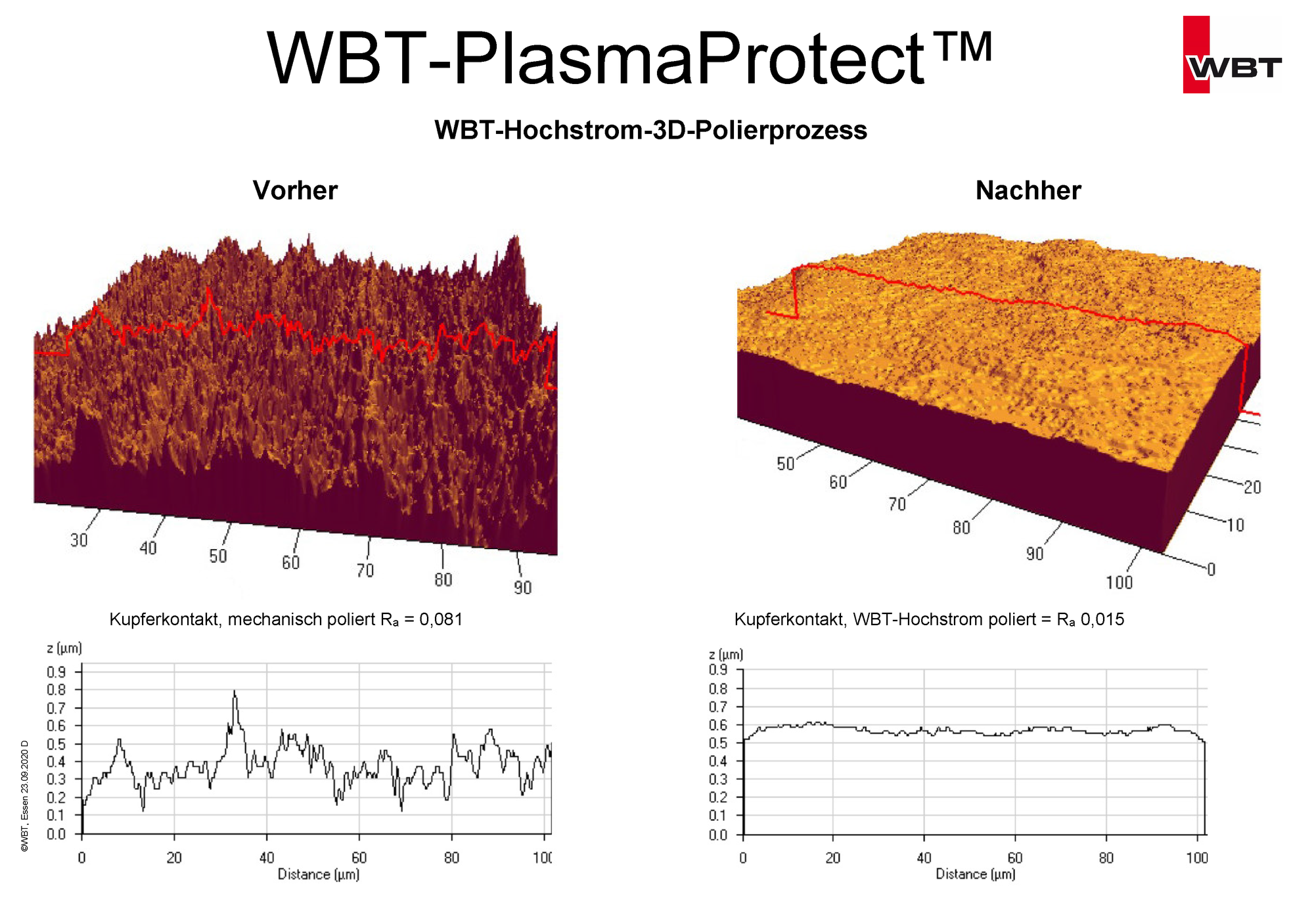

1) The surface roughness of the signal conductor, which is damaging to the contact,

is significantly smoothed through pre-treatment with high-current polishing so

that the “Van der Waals forces” can be activated considerable more strongly,

thus making it possible to plate directly in the PVD process, see attached graphic.

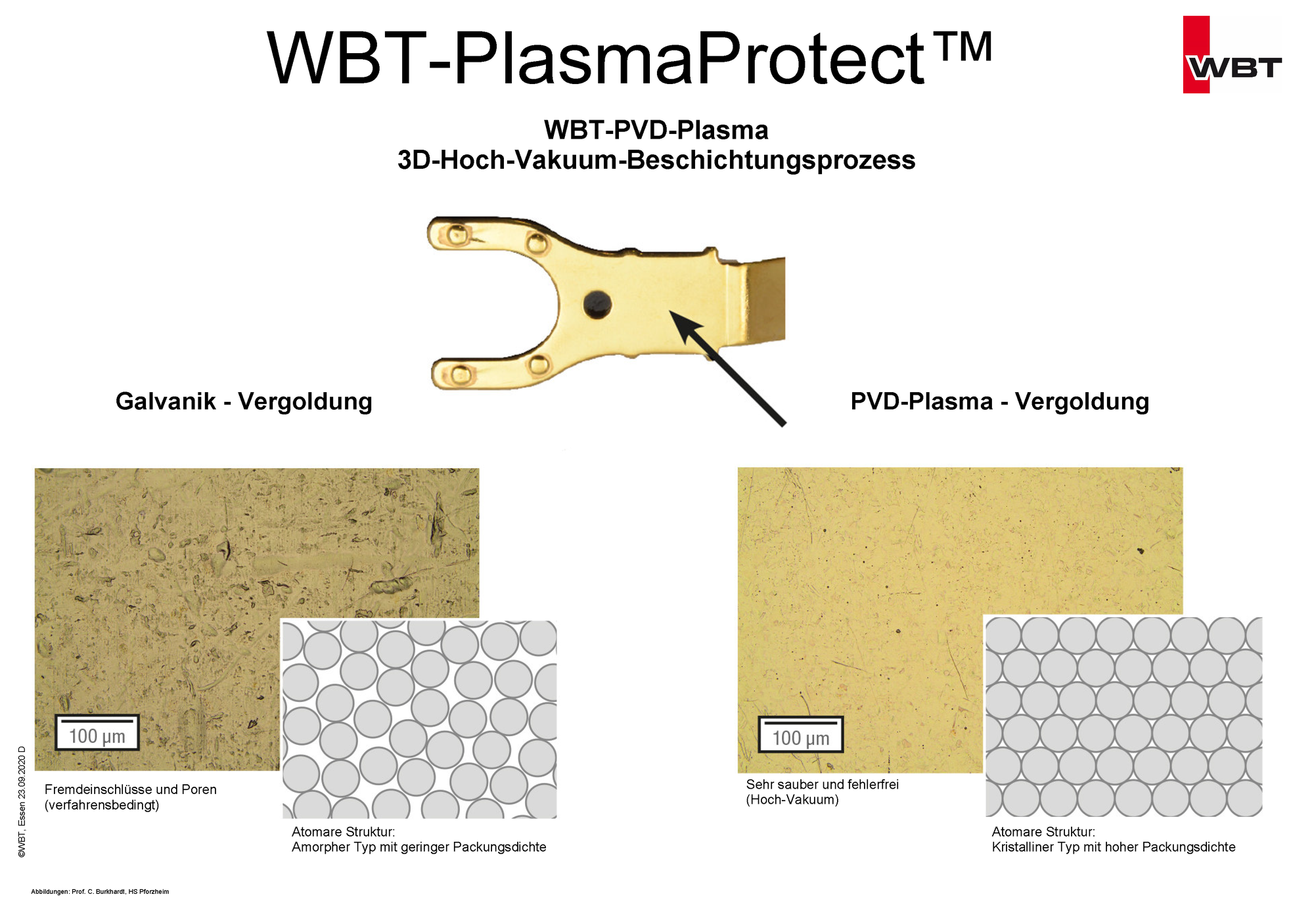

2) The PVD (gold) surface is faultless and pure (high vacuum), has a crystalline

structure, is thinner and at the same time more flexible with good elastic

deformability (Hertzian stress) for improved contact quality.

In addition, an award was given for four further development achievements which form the basis for the leap from previous electroplating to modern PVD plasma technology:

1) The 3D coating in PVD plasma, combined with the improvement of effectiveness

from approx. 20 to 80%,

2) The energy saving of approx. 26%,

3) The conservation of resources (saving of gold) of approx. 35%, and

4) The reduction of environmental impact owing to the elimination of toxic

electroplating baths.

The process development with the direct connection between high-current polishing and PVD plasma coating allows for improvements in quality, reduction of the burden on the environment and conservation of resources. In principle, this new technique can be used for all plug-in connectors, e.g. in measurement and control technology. Particularly where large bandwidth and high current carrying capacity, and at the same time improved long-term stability, are desired.

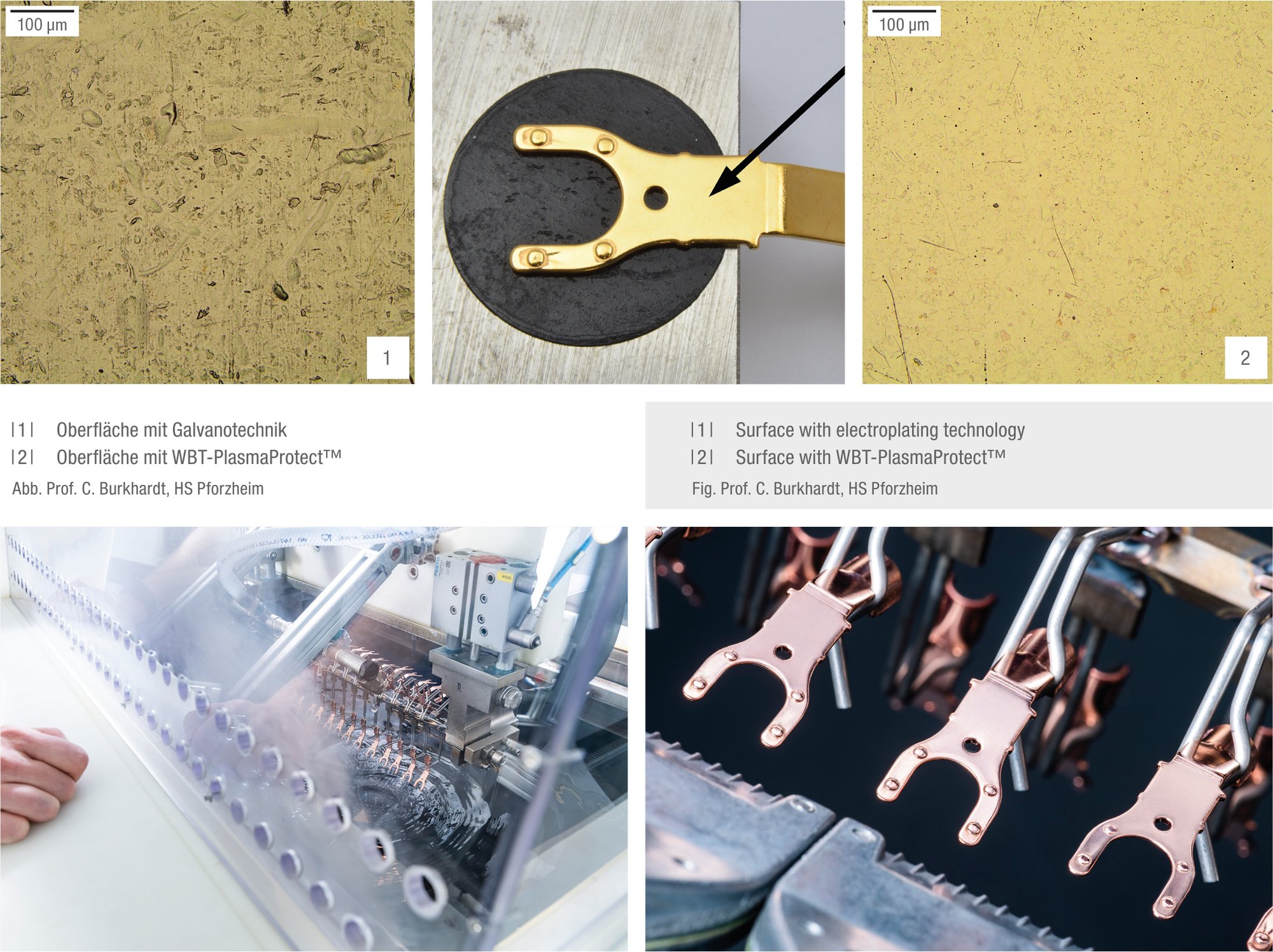

For numerous years, enthusiasts of outstanding sound quality have been enjoying the nextgen™ connectors of WBT. With their sophisticated signal conductors made of pure copper or fine silver in combination with innovative functional materials, the nextgen™ series offers everything the audiophile heart desires. By optimising the mass of the signal conductor, WBT managed to minimise mass storage effects and eddy currents. The sound is clearer, and notably more substantial and spatial. However, WBT goes even further. The think tank of WBT has been working tirelessly for some years. According to the principle that the best is still not good enough, WBT is seeking to improve the nextgen™ principle even more. This endeavour often seemed very difficult. The in-house production facilities in Essen had to be restructured. A PVD plasma production line had to be established. Already during the construction phase, dedicated production processes particularly designed for WBT were developed and implemented on a newly established production line.

However, what does PVD plasma production mean?

Contacts have to be protected against corrosion. Around the world, this is done for connectors almost exclusively by using electroplating technology. WBT is the first manufacturer of connectors replacing electroplating by the much more precise PVD technology. The innovative nanotechnology replaces the obsolate electroplating technology. For this process, the signal conductors made of pure copper are cleaned in a high current polishing line and the surface is polished to a high glossy finish. This is done completely without any harmful chemical additives. The resulting surface is absolutely pure without any imperfections like chemical inclusions. Afterwards, the conductor is subject to physical vapour deposition (PVD) for a physical fine gold plating. In this process, atomic gold is released by plasma discharge ignition in a high vacuum. In the vacuum, this gold is literally shot on the copper conductor to realise atomic bonding* for inseperably anchoring (*Van der Waals forces). The result is a homogeneous material compound with a 24-carat gold surface.

And why plasma?

The choice of plasma can be easily explained. With their nextgen™ principle, WBT had already initiated a transition to environmentally friendly technologies. The replacement from galvanic surface coating to PVD plasma is just the consequent continuation of this basic thought. In contrast to environmentally harmful electroplating, plasma technology does not require any toxic electroplating baths and is environmentally neutral. Additionally, the new procedure enables reduction of the energy consumption by approx. 25 %. And resource-saving use of precious metals can also be ensured.

What are the consequences for the sound?

The atomically boundesd gold ensures a hard and still flexible surfaces with resistance against scratches and abrasion. Even more important is the structure in the material itself. Thanks to PVD plasma technology, a defined crystalline structure is generated. As electricity is direction-dependent, this structure enables even further increase in precision of the signal flow for unparalleled signal quality. While nextgen™ connectors have improved sound quality by increased clarity, substance and spatiality, WBT-PlasmaProtect™ offers even more defined sound. While wishing an orchestra is playing in the living room at home, this technology now offers the sensation of being at the centre of the orchestra. When closing the eyes, it sounds like standing between the strings or brass section – and suddenly next to the kettledrum. One is left with the impression of not only being a listener but a part of the orchestra itself. With WBT-PlasmaProtect™, WBT managed to realise a leap in quality for audio connectors.

The general public is more aware of brand piracy where luxury goods are concerned. It is not widely known that the hi-fi industry is also seriously affected.

Brand piracy is a serious problem for the manufacturers and users of quality branded products.

In recent years the circulation of counterfeit products has reached such enormous dimensions that the world-wide economy is affected.

Consumers suffer from counterfeit products because the counterfeits are usually not recognisable as such but have a poorer performance and durability. In the worst case, they can severely damage other hardware.

This in turn has a negative impact on the manufacturers, whose brand image can be seriously damaged.

WBT is aware of the fact that counterfeit of WBT connectors are circulating not only within Europe but also world-wide. We are committed to removing these illegal products from the market and will prosecute vigorously in the criminal and/or civil courts manufacturers and distributors who undermine the integrity of the WBT brand by their activities.

Remember: if the price is too good to be true you are probably not buying genuine WBT connectors! If you are not sure of your connectors´origin, contact your WBT dealer or WBT directly! We will help you verify your purchase.

WBT-Industrie GmbH

Telefon:0049 2054 – 87552 -50

sales@wbt.de